Yc-8101a Chophimba cha Ceramic Chosamatirira cha Porcelain Nano-composite (Chakuda)

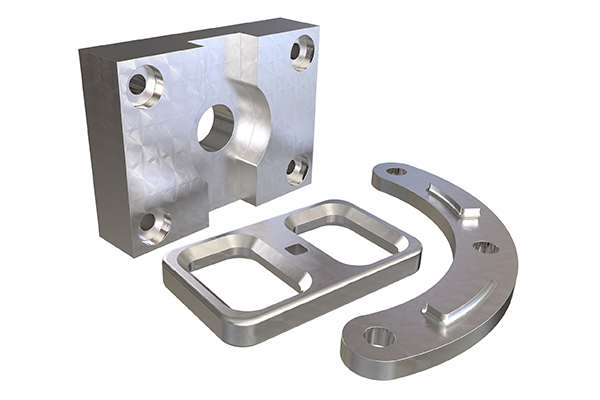

Zigawo za malonda ndi mawonekedwe ake

(Zophimba za ceramic zokhala ndi zigawo ziwiri)

YC-8101A-A:Chophimba cha gawo A

YC-8101A-B: Wothandizira kuchiritsa gawo la B

Mitundu ya YC-8101:chowonekera, chofiira, chachikasu, chabuluu, choyera, ndi zina zotero. Kusintha mtundu kungapangidwe malinga ndi zosowa za makasitomala

Chogwiritsiridwa ntchito

Malo a zinthu zosiyanasiyana monga mapoto osamata amatha kupangidwa ndi chitsulo, chitsulo chofewa, chitsulo cha kaboni, chitsulo chosapanga dzimbiri, aluminiyamu, titaniyamu, chitsulo cha aloyi chotentha kwambiri, galasi la microcrystalline, ziwiya zadothi, ndi zina zotero.

Kutentha komwe kungagwiritsidwe ntchito

- Kutentha kwakukulu kokana ndi 800℃, ndipo kutentha kwa nthawi yayitali kogwira ntchito kuli mkati mwa 600℃. Sichimakhudzidwa ndi kukokoloka mwachindunji ndi malawi kapena mpweya wotuluka kutentha kwambiri.

- Kukana kutentha kwa chophimbacho kumasiyana malinga ndi kukana kutentha kwa zinthu zosiyanasiyana. Kukana kuzizira ndi kutentha komanso kugwedezeka kwa kutentha.

Zinthu zomwe zili mu malonda

- 1. Zophimba zazing'onozi ndi zochokera m'madzi okha, zotetezeka, zoteteza chilengedwe komanso zopanda poizoni.

- 2. Zipangizo za nano-composite ceramics zimakhala ndi vitrification yolimba komanso yosalala pa kutentha kochepa kwa 250℃, komwe kumasunga mphamvu komanso kokongola.

- 3. Kukana mankhwala: Kukana kutentha, kukana asidi, kukana alkali, kutchinjiriza kutentha, kukana kutentha kwambiri, komanso kukana mankhwala, ndi zina zotero.

- 4. Chophimbacho chimapirira kutentha kwambiri komanso kutentha mkati mwa makulidwe enaake (pafupifupi ma microns 30), ndipo chimakhala ndi kutentha kwabwino (cholimbana ndi kutentha, ndipo sichimasweka kapena kung'ambika nthawi yonse ya ntchito ya chophimbacho).

- 5. Chophimba cha nano-inorganic ndi chokhuthala ndipo chili ndi mphamvu yokhazikika yoteteza magetsi, ndipo choteteza chimatha kupirira mphamvu yamagetsi ya pafupifupi 1000 volts.

- 6. Ili ndi kutentha kokhazikika komanso kwabwino komanso mphamvu yabwino kwambiri yolumikizirana.

- 7. Kuuma: 9H, kukana malawi otseguka ndi kutentha kwambiri mpaka madigiri 400, kunyezimira kwambiri, komanso kukana kuvala kwambiri

Minda yogwiritsira ntchito

1. Zigawo za boiler, mapaipi, ma valve, zosinthira kutentha, ma radiator;

2. Magalasi a microcrystalline, zida ndi zida, zipangizo zachipatala, zida zamankhwala, ndi zida za majini achilengedwe;

3. Zipangizo zotentha kwambiri ndi zida zoyezera kutentha kwambiri;

4. Malo a zida zachitsulo, nkhungu, ndi zida zoponyera zinthu;

5. Zinthu zotenthetsera zamagetsi, matanki, ndi mabokosi;

6. Zipangizo zazing'ono zapakhomo, ziwiya za kukhitchini, ndi zina zotero.

7. Zigawo zotentha kwambiri zamakampani opanga mankhwala ndi zitsulo.

Njira yogwiritsira ntchito

(Kuti muwonetsetse kuti zotsatira zake ndi zabwino, tikukulimbikitsani kuti mugwiritse ntchito motere)

1. Zigawo ziwiri:Tsekani ndi kupukuta mu chiŵerengero cha kulemera kwa 2:1 kwa maola awiri mpaka atatu. Chophimba chotsukidwacho chimasefedwa kudzera mu sikirini ya fyuluta ya ma mesh 400. Chophimba chosefedwacho chimakhala chophimba cha nano-composite ceramic chomalizidwa ndipo chimayikidwa pambali kuti chigwiritsidwe ntchito pambuyo pake. Utoto wotsalawo uyenera kugwiritsidwa ntchito mkati mwa maola 24; apo ayi, magwiridwe ake adzachepa kapena kulimba.

2. Kuyeretsa zinthu zoyambira:Kuchotsa mafuta ndi dzimbiri, kukanda pamwamba ndi kupukuta mchenga, kupukuta mchenga ndi kalasi ya Sa2.5 kapena kupitirira apo, zotsatira zabwino kwambiri zimapezeka popukuta mchenga ndi 46-mesh corundum (white corundum).

3. Kutentha kwa kuphika: 270℃ kwa mphindi 30 (Ikhoza kuchiritsidwa kutentha kwa chipinda. Poyamba ntchito yake ndi yoipa pang'ono, koma imatha kubwerera mwakale pakapita nthawi.)

4. Njira yomangira Kupopera:Chogwirira ntchito chomwe chiyenera kupopedwa chiyenera kutenthedwa mpaka madigiri 40 Celsius musanapope; apo ayi, chingagwe kapena kufooka. Ndikofunikira kuti makulidwe a kupopedwa akhale mkati mwa ma microns 30. Chingathe kupopedwa kamodzi kokha.

5. Chithandizo cha zida zokutira ndi chithandizo cha zokutira

Kugwiritsa ntchito zida zophikira: Tsukani bwino ndi ethanol yosalowa madzi, ikani mu uvuni ndi mpweya wopanikizika ndipo sungani.

6. Chithandizo cha kupaka: Mukamaliza kupopera, siyani kuti ziume mwachilengedwe pamwamba pa madzi kwa mphindi pafupifupi 30. Kenako, ziyikeni mu uvuni wotentha madigiri 250 ndipo zisungeni kutentha kwa mphindi 30. Mukazizira, zichotseni.

Wapadera kwa Youcai

1. Kukhazikika kwaukadaulo

Pambuyo poyesa mwamphamvu, njira yaukadaulo wa nanocomposite ceramic imakhalabe yokhazikika pamikhalidwe yovuta kwambiri, yolimbana ndi kutentha kwambiri, kutentha kwambiri komanso dzimbiri la mankhwala.

2. Ukadaulo wofalitsa zinthu zopanda madzi

Njira yapadera yofalitsira imatsimikizira kuti tinthu tating'onoting'ono timagawidwa mofanana mu utoto, kupewa kusonkhana. Kuchiza bwino mawonekedwe kumawonjezera mgwirizano pakati pa tinthu tating'onoting'ono, kukulitsa mphamvu yolumikizana pakati pa utoto ndi substrate komanso magwiridwe antchito onse.

3. Kuwongolera kophimba

Mapangidwe olondola komanso njira zophatikizika zimathandiza kuti mawonekedwe a utoto azitha kusinthika, monga kuuma, kukana kuwonongeka komanso kukhazikika kwa kutentha, zomwe zimakwaniritsa zofunikira pakugwiritsa ntchito kosiyanasiyana.

4. Makhalidwe a kapangidwe ka micro-nano:

Tinthu tating'onoting'ono ta nanocomposite ceramic timakulunga tinthu ta micrometer, timadzaza mipata, timapanga chophimba chokhuthala, ndikuwonjezera kukhuthala ndi kukana dzimbiri. Pakadali pano, tinthu tating'onoting'ono timalowa pamwamba pa substrate, ndikupanga interphase yachitsulo-ceramic, yomwe imawonjezera mphamvu yolumikizirana ndi mphamvu yonse.

Mfundo yofufuza ndi chitukuko

1. Vuto lofanana ndi kukula kwa kutentha:Ma coefficients okulitsa kutentha kwa zitsulo ndi zinthu zadothi nthawi zambiri amasiyana panthawi yotenthetsera ndi kuziziritsa. Izi zingayambitse kupangika kwa ming'alu yaying'ono mu pulasitiki panthawi yotenthetsera kutentha, kapena ngakhale kung'ambika. Pofuna kuthana ndi vutoli, Youcai wapanga zida zatsopano zophikira zomwe coefficient of thermal expansion ili pafupi ndi ya substrate yachitsulo, motero amachepetsa kupsinjika kwa kutentha.

2. Kukana kutentha ndi kugwedezeka kwa kutentha: Pamene chophimba chapamwamba chachitsulo chikusintha mofulumira pakati pa kutentha kwakukulu ndi kochepa, chiyenera kukhala chokhoza kupirira kutentha komwe kumachitika popanda kuwonongeka. Izi zimafuna kuti chophimbacho chikhale ndi kukana kutentha kwambiri. Mwa kukonza kapangidwe kake ka utoto, monga kuwonjezera kuchuluka kwa ma phase interfaces ndikuchepetsa kukula kwa tirigu, Youcai imatha kuwonjezera kukana kutentha.

3. Mphamvu yolumikizirana: Mphamvu yolumikizirana pakati pa chophimba ndi chogwirira chachitsulo ndi yofunika kwambiri kuti chophimbacho chikhale chokhazikika komanso cholimba kwa nthawi yayitali. Kuti chiwonjezere mphamvu yolumikizirana, Youcai amayambitsa gawo lapakati kapena gawo losinthira pakati pa chophimba ndi chogwirira kuti chikhale chonyowa komanso chogwirira mankhwala pakati pa ziwirizi.